WHICH IS THE BEST VALVE?

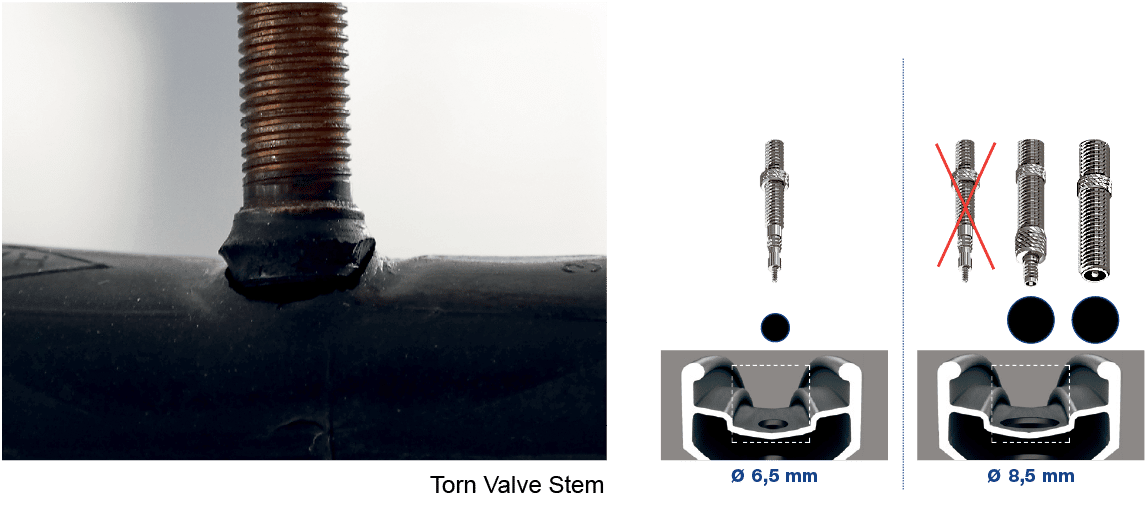

Caution: Be aware that using Sclaverand valve tubes on rims with larger valve holes often leads to a valve tear off when the sharp metal edges around the valve hole cut the valve stem off the tube.

WHAT IS THE PURPOSE OF A RIM NUT?

The rim nut fixes the valve in the rim. Some regard it as unnecessary. And indeed, you may well ride your bicycle without a rim nut. It is however helpful when attaching the pump connector, as particularly when the pressure is low the valve may fall inside the rim. With some rims there may be a rattle if the valve is not fixed.

The rim nut must only be tightened by hand. Never tighten the rim nut with pliers, as this can lead to tube damage.

WHAT CAUSES A VALVE TEAR OFF?

In most cases valve tear off is due to tire slip. Continual improvement in brake performance and low inflation pressures often cause the tire to slip on the rim. The tire movement then drags the tube and this can lead to the valve shearing off.

WHAT CAN BE DONE TO PREVENT TIRE SLIP OR VALVE TEAR OFF?

A higher inflation pressure considerably reduces the tire slip. Of course a higher tire pressure is not always desired.

We implement Limited Slip Technology (LST) in Schwalbe MTB-folding and balloon tires. The tire bead is coated with a special rubber layer that produces a dramatic reduction in tire/rim slip.

The Schwalbe Downhill tube has a highly reinforced valve foot.

Theoretically, the use of talcum powder is also helpful. This can reduce the friction between tire and tube. However in practice, if talcum powder gets between tire and rim, it will increase the problem.

Some rims have such slippery surfaces that even LST does not suffice one hundred percent. It will help if the rim contact area with the tire is lightly abraded with sandpaper (180 grade). This considerably increases the friction between tire and rim.

The problem is very much reduced with disc brakes because the rims do not get hot through braking.

There is no valve tear off with tubeless tires. The tire can move without causing problems.