AEROTHAN TUBE

DIFFERENT BY CONVICTION

Aerothan is a material that completely redefines the bicycle inner tube: extremely light, highly puncture-resistant and designed for the lowest rolling resistance.

DEVELOPMENT

In the development of Aerothan Tubes Schwalbe has gone new ways from the beginning. The result is a high-end alternative to conventional bicycle tubes. Schwalbe wants to offer the optimum product for every cyclist. When it comes to high-end bicycle inner tubes, this becomes an exciting challenge. The engineers have to reconcile the apparent opposites of lowest weight and highest puncture resistance. A case for the Schwalbe Innovation Lab, where material compositions and design principles are redeveloped to create unprecedented products. This is how the Aerothan Tube was created, which not only meets but exceeds the expectations of a high-end bicycle tube.

ADVANTAGES OF AEROTHAN TUBES

- Consistently light to the valve

- Minimal rolling resistance - maximum riding dynamics

- Extremely heat resistant - approved for rim brakes

- Stable ride - even at low air pressures

- Easy mounting - without slipping or jamming

- Made in Germany

- 100 % recyclable

to the test rating

"To ride with tubes or not - that is often a question of faith for us road cyclists. If it should be tubes, Aerothan is in any case the first choice. Compared to conventional tubes, more than 100g can be saved per set of tires - a lot of weight tuning for relatively little money. And the difference is also felt to the maximum when accelerating; the lower rolling resistance thrills me."

Cycling legend

"Try getting hold of a bottle of sealing milk in places like the Mongolian Taiga - that's the reason I'll be riding bike tubes in the future. Ideally, always with some Aerothan Tubes in my luggage. Because they are not only lighter than conventional tubes, but also take up less space. In addition, I can simply rely on the extreme puncture resistance. Aerothan is a bit more expensive to buy. But with high mileage, it quickly pays for itself."

Extreme athlete and six-time world record holder

Aerothan tubes are around 40% lighter than a comparable Schwalbe Extralight tube made of butyl

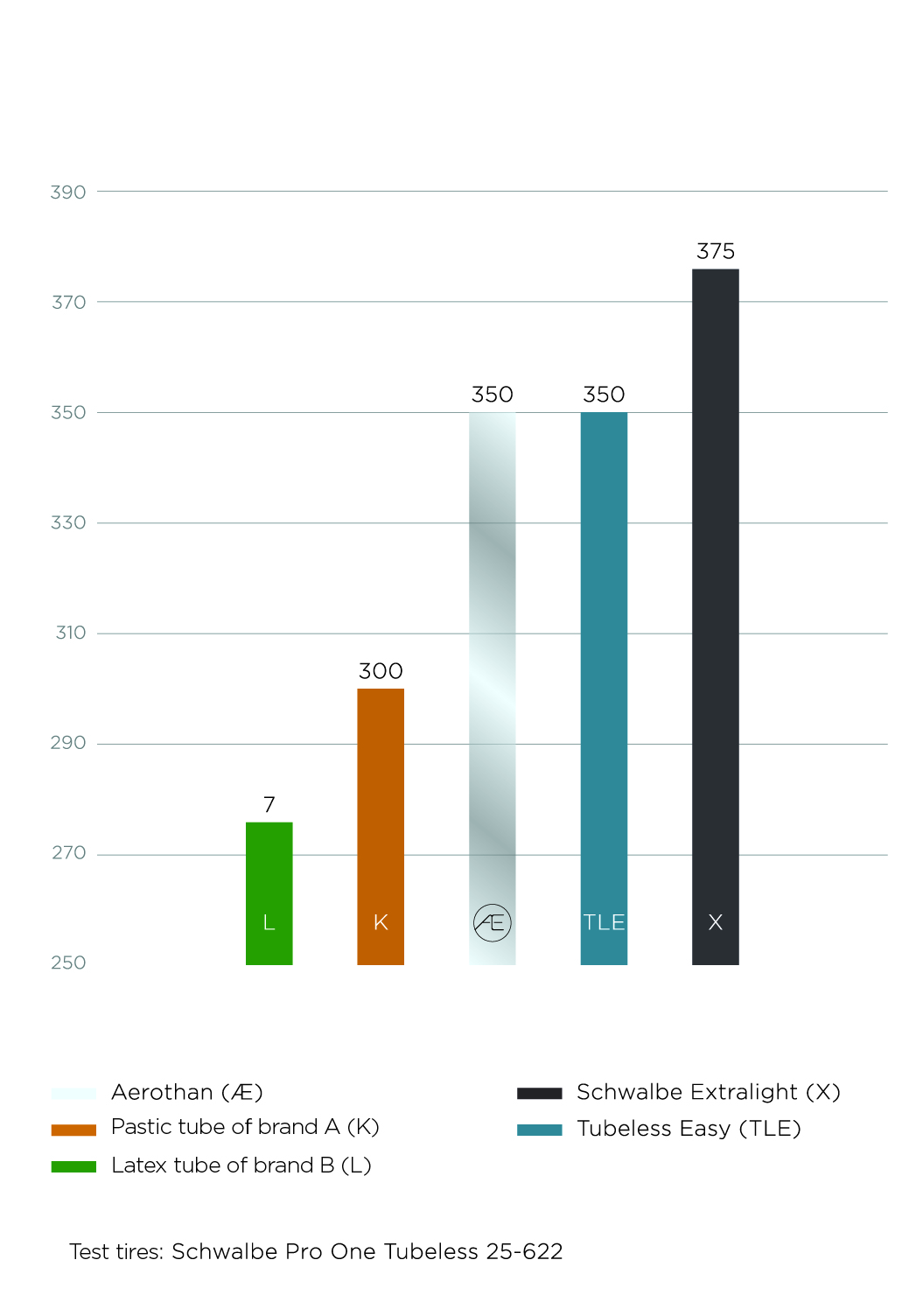

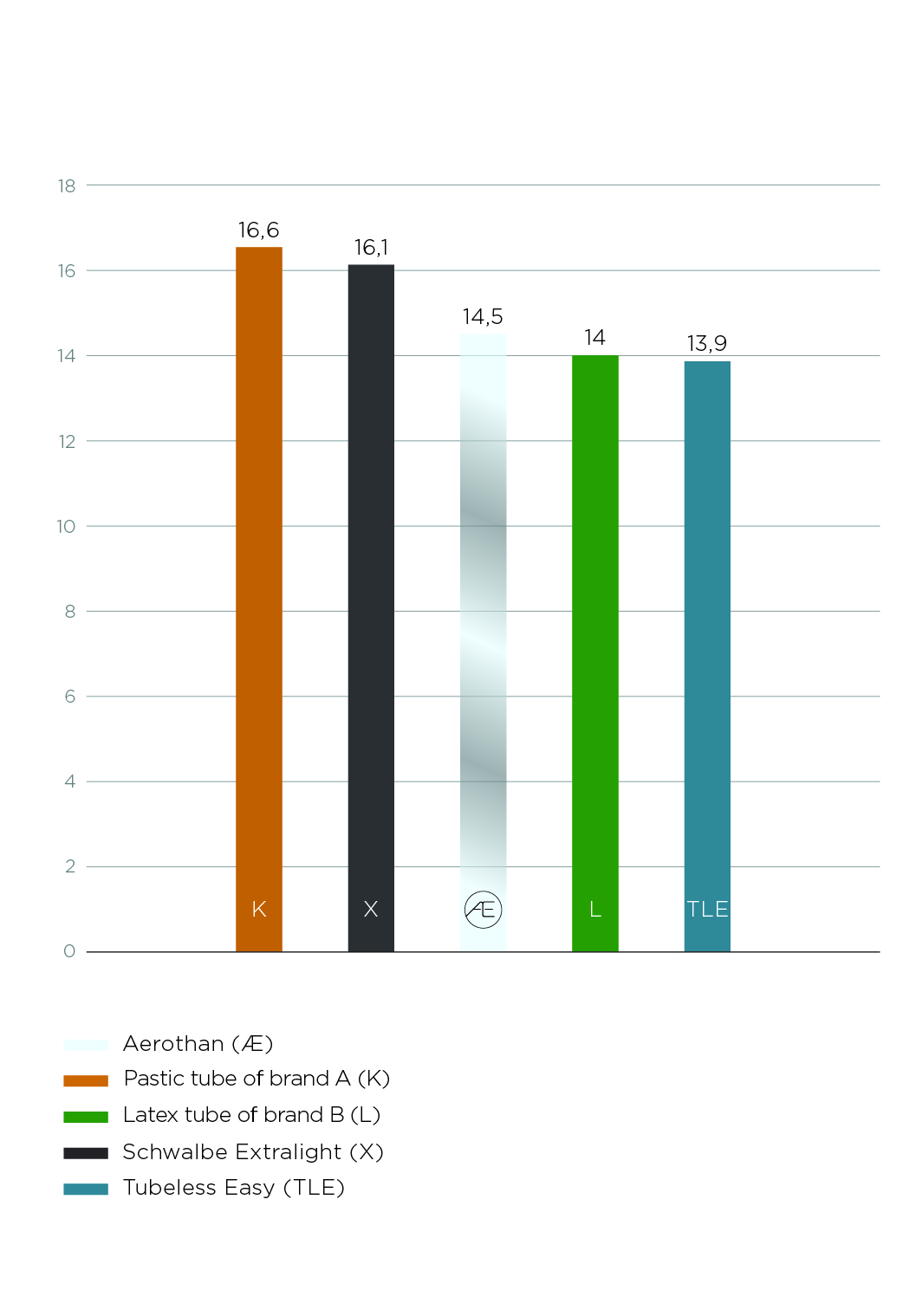

Aerothan Tubes have an extremely low rolling resistance at tubeless level.

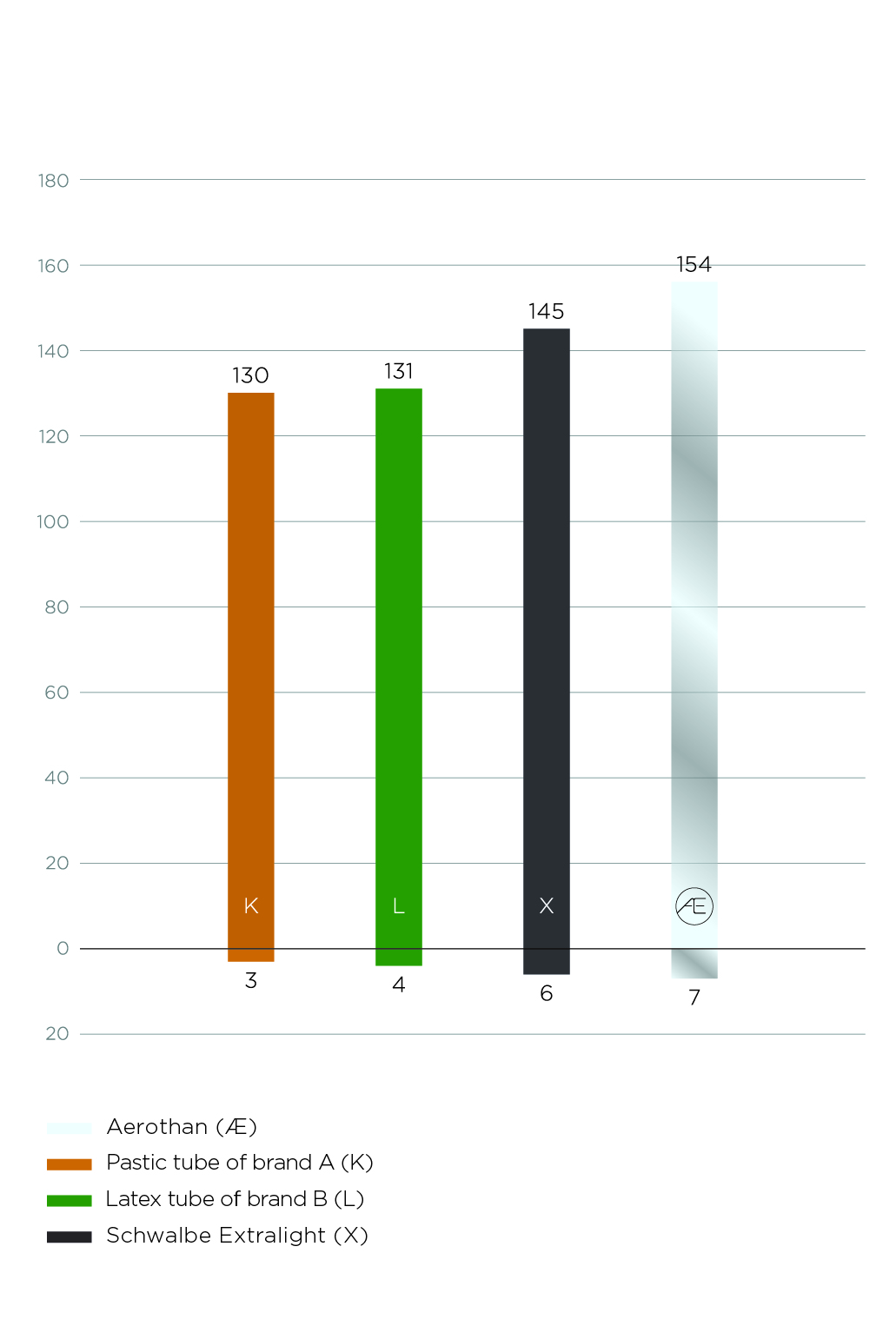

Aerothane tubes prevent sudden air loss thanks to the high level of puncture protection

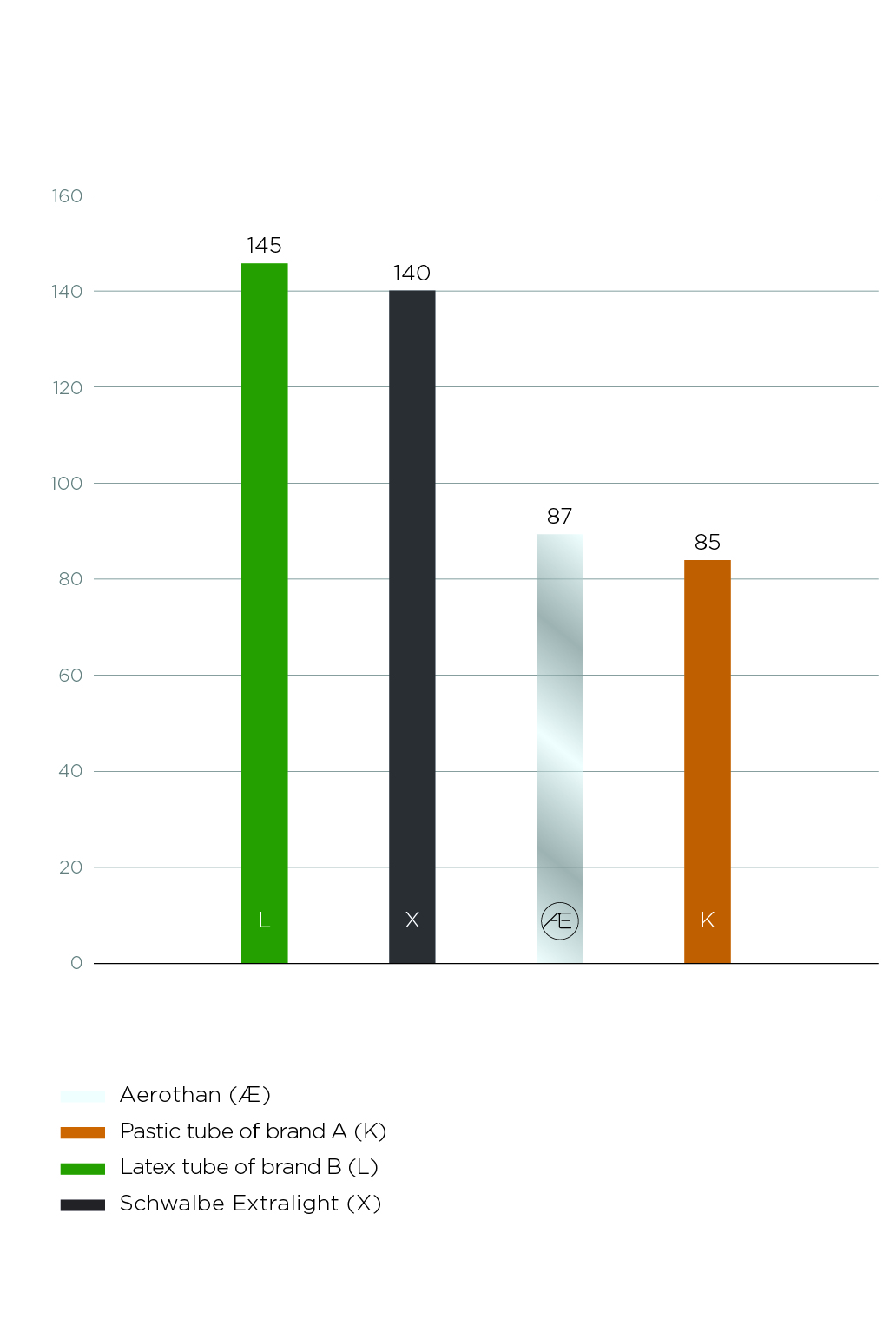

Aerothan tubes are around 40% lighter than a comparable Schwalbe Extralight tube made of butyl

Aerothan Tubes have an extremely low rolling resistance at tubeless level.

Aerothane tubes prevent sudden air loss thanks to the high level of puncture protection

AEROTHAN TUBE - THE FACTS

- 40% LIGHTER

Aerothan Tubes are about 40% lighter than a comparable Schwalbe Extralight tube made of butyl. - EXTREMELY LOW ROLLING RESISTANCE

Aerothan Tubes have an extremely low rolling resistance at tubeless level. - INCREASED PUNCTURE PROTECTION

Aerothan Tubes offer increased puncture protection. The high puncture protection prevents sudden air loss.

AEROTHAN IS 100% RECYCLABLE

Aerothan Tubes are made of 100% thermoplastic polyurethane (TPU) (including the valve) and are therefore fully recyclable. Work is currently underway to recycle used tubes and process them into new tubes.

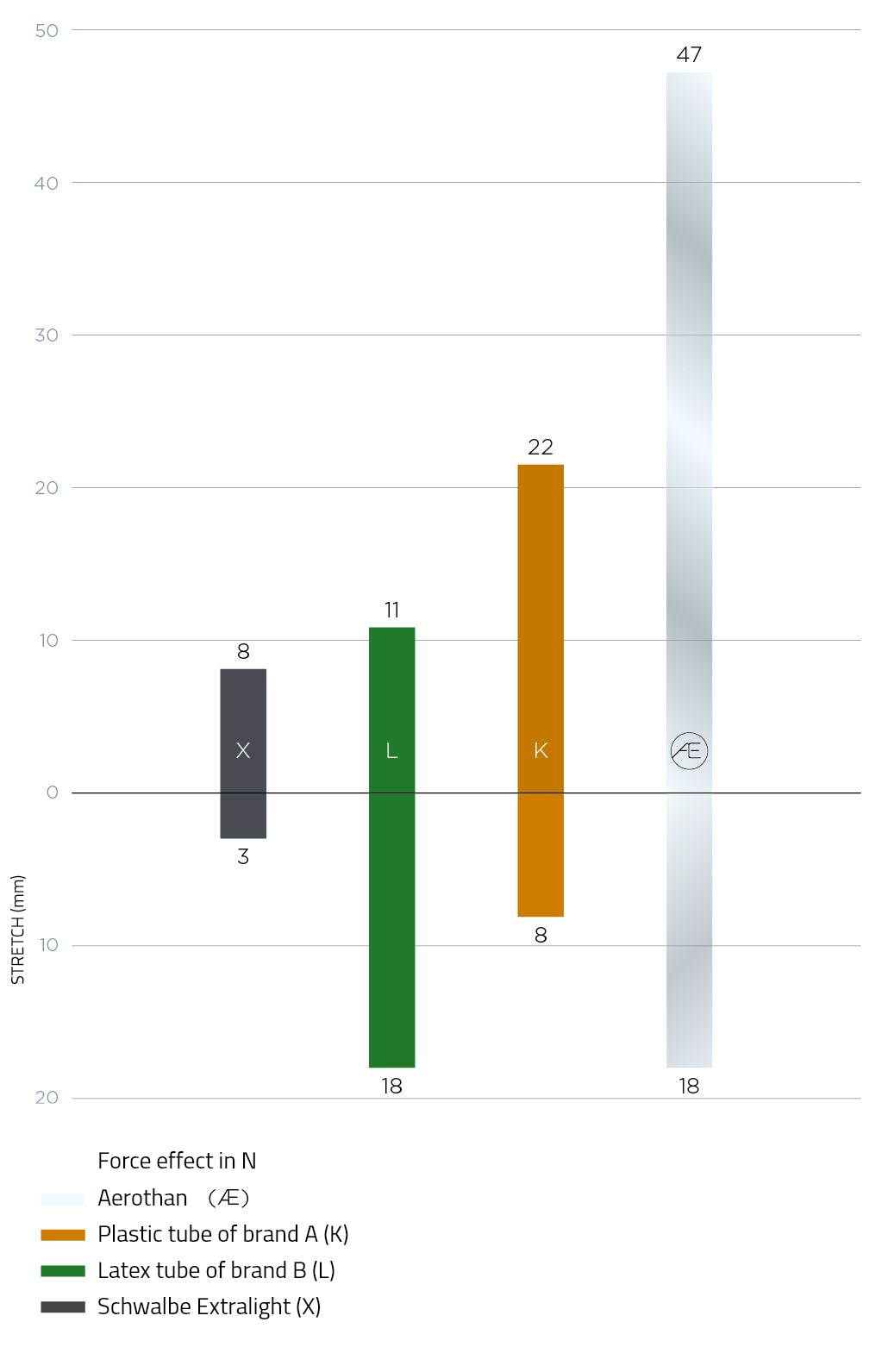

AEROTHAN SETS STANDARDS - ALSO IN TESTING

Before a Schwalbe innovation is ready for the market, we test the product intensively in numerous tests. The test values of the Aerothan Tube speak for themselves.

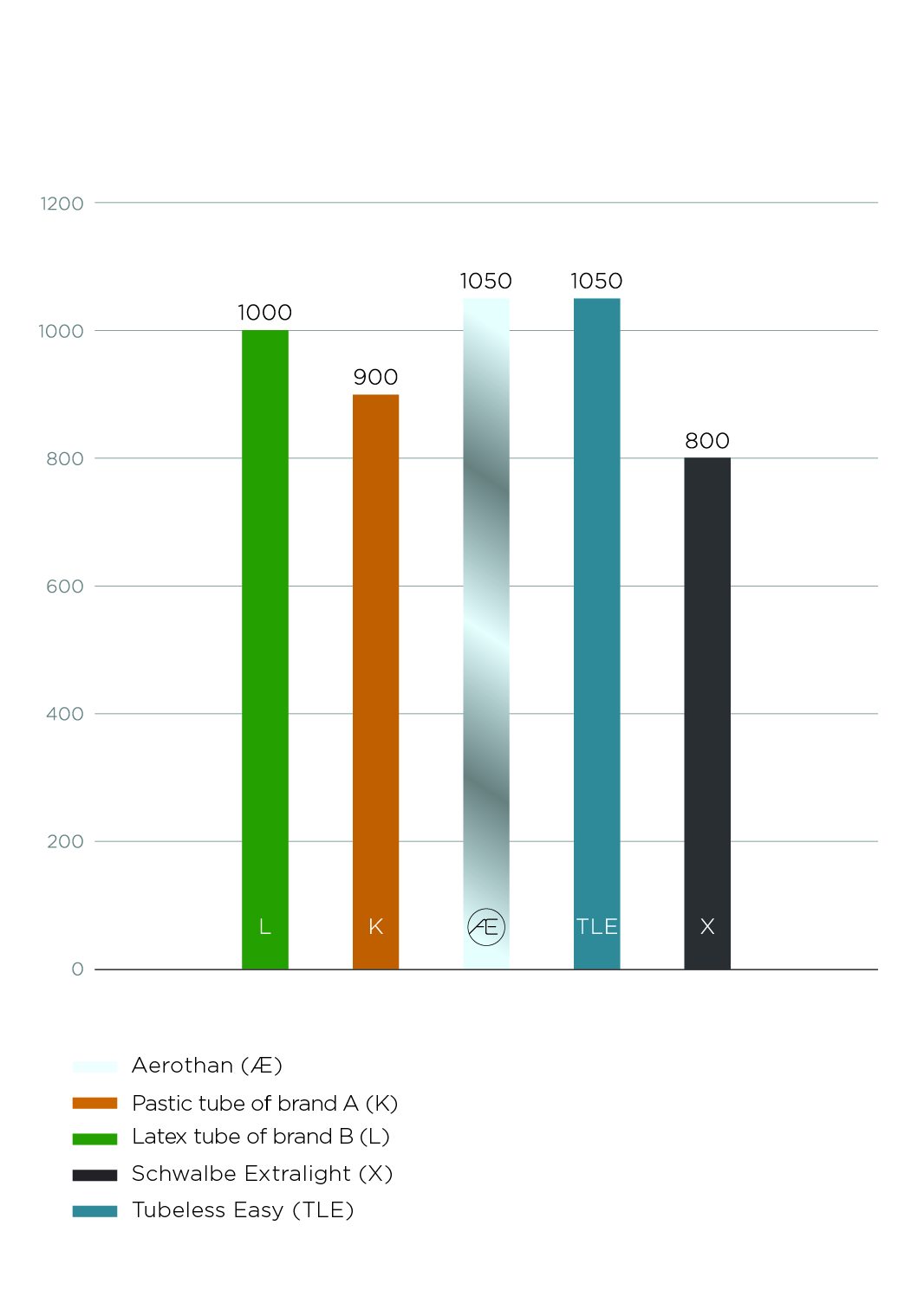

PLUNGER TEST

SNAKE BITE TEST (ROAD)

SNAKE BITE TEST (MTB)

WEIGHT

ROLLING RESISTANCE

HEAT RESISTANCE DYNAMIC

TUBES

AEROTHAN TUBE RACE

AEROTHAN TUBE ALLROUND

The Aerothan Tube Allround is the extremely light and absolutely reliable high-end tube for city and tour. Compared to Schwalbe standard tubes, it makes the wheel about 180 grams lighter - together with the low rolling resistance a guarantee for much more riding fun. You can rely on its puncture protection even on longer rides in nature. Even if you forget to re-inflate, the Aerothan Tube Allround does not take it badly: It remains dimensionally stable even at low air pressure and keeps the bike safely on track.

AEROTHAN TUBE MTB

The Aerothan Tube MTB is as puncture resistant against snakebites as it is against sidewall damage - the extreme robustness of the material ensures this. " less

In cross-country and marathon use, the amazingly low weight and low rolling resistance play their advantages. Even on demanding trails, this tube never lets you down: Because the Aerothan Tube MTB remains extremely dimensionally stable even at low air pressures, you have your bike always reliably under control.

"With Aerothan I know that everything is good, that gives me security. I ride it in combination with the Schwalbe Pro One TT and am incredibly happy with it because of the extremely low weight and the super good rolling resistance."

Ironman World Champion

PRODUCT OVERVIEW

| RACE

|

ENDURANCE RACE

|

ALLROUND

|

MTB

|

MTB

|

CARGO/BMX

|

|||||||

| Field of application |

Road | Road/CX/Gravel | Trekking/Touring/ Gravel |

XC/Marathon/Trail/Enduro | XC/Marathon/Trail/Enduro | Cargo/BMX | ||||||

| Designation | SV20E | SV16E | SV17E |

|

|

SV7E | ||||||

| Wheel size |

28 “ | 28 “ | 28 “ |

|

|

20 “ | ||||||

| ETRTO | 23-622 to 28-622 |

28-622 to 35-622 |

37-622 to 50-622 |

|

|

54-406 to 62-406 |

||||||

| recommended Tire/rim combination * | 28-622 I 19C | 28-622 I 21C | see ETRTO chart |

|

|

62-406 | 30C | ||||||

| Valve | SV, 40/60/80/100 mm |

SV, 40/60/80 mm |

SV, 40/60 mm |

|

|

SV, 40 mm | ||||||

| Pack size |

28 x 80 mm | 32 x 80 mm | 38 x 80 mm |

|

|

54x71 mm | ||||||

| Weight | 41 g | 50 g | 61 g |

|

|

65g | ||||||

| 100 % recyclable |  |

|

|

|

|

|

||||||

| Made in Germany |  |

|

|

|

|

|

||||||

| Suitable for rim brakes |  |

|

|

|

|

|

AEROTHAN PLUS TIRES

| ALLROUND+

|

MTB+

|

CARGO/BMX+

|

|||||

| Field of application |

Trekking/Touring/ Gravel |

XC/Marathon/Trail/Enduro | Cargo/BMX | ||||

| Designation | AV17E+ SV17E+ |

|

AV7E+ | ||||

| Wheel size |

28 “ |

|

20 “ | ||||

| ETRTO | 37-622 to 50-622 |

|

54-406 to 62-406 |

||||

| recommended Tire/rim combination * | see ETRTO chart |

|

62-406 | 30C | ||||

| Valve | AV, SV, 40 mm |

|

AV, 40 mm | ||||

| Pack size |

38 x 80 mm |

|

54 x 71 mm | ||||

| Weight | 85 - 86 g |

|

88g | ||||

| 100 % recyclable |  |

|

|

||||

| Made in Germany |  |

|

|

||||

| Suitable for rim brakes |

|

|

|

FAQ

GENERAL

What exactly is Aerothan?

Aerothan is a special thermoplastic polyurethane that Schwalbe developed together with BASF. It serves as the base material for high-end bicycle inner tubes, the Aerothan Tubes, which are manufactured in Germany using a patented welding process.

What are the advantages of Aerothan?

Aerothan Tubes are extremely lightweight yet highly puncture resistant. The low rolling resistance provides a very dynamic riding experience. The dimensionally stable Aerothan gives the respective bike high riding stability even at low air pressures. At the same time, the dimensional stability allows for easy installation, because the tube does not slip and can not be pinched. To the Aerothan material is very heat resistant, so that all Aerothan hoses are also compatible with rim brakes.

Does Aerothan have advantages over Tubeless?

Schwalbe is the expert for tubeless tires. However, there are riders who prefer to ride with tubeless even in the tubeless age. There are also wheels that are not suitable for tubeless. For these cases we have developed Aerothan Tubes - the high-end alternative to the conventional bicycle tube, whose technical advantages are on a par with a tubeless system in many respects.

For which tire sizes are Aerothan Tubes available?

Aerothan Tubes are available for the most common tire sizes in the areas: Road, Allround and MTB. An overview of all sizes can be found in the table above.For which applications are Aerothan Tubes suitable?

Aerothan Tubes are available in the categories Road, Allround and MTB. Due to the special material properties, Aerothan is extremely versatile. An overview of all areas of application can be found in the table above.

Are there tolerances/discrepancies in weight?

Aerothan is a flexible material and is subject to limited tolerances (unlike solids, such as metal). Despite the most sophisticated manufacturing and inspection processes, weight variations of +/- 5% may occur.

Are Aerothan Tubes recyclable?

Like all Schwalbe tubes, Aerothan Tubes are 100% recyclable. In contrast to classic butyl tubes, Aerothan Tubes are made entirely of a thermoplastic polyurethane - including the valve. This simplifies the recycling process even further. Just like all other Schwalbe tubes, Aerothan Tubes can be returned to us through our tube recycling program. Recycling as a bicycle inner tube is not yet possible with Aerothan; instead, the recycled tubes are given a second life, e.g. as a seal or insulation material.

Do extreme temperatures affect the Aerothan Tube?

Aerothan is extremely temperature stable. The material can withstand both high temperatures of up to +70°C and cold temperatures of down to -50°C without any problems.

MAINTENANCE & REPAIR

Can I repair Aerothan Tubes?

The Aerothan Tube can be repaired without any problems using Schwalbe Glueless Patches. Roughening as with the butyl tube is not necessary (! do not use sandpaper!), instead the self-adhesive patches are applied directly to the area to be patched. For this, the surface should be as clean as possible. The use of rubbing alcohol is recommended to improve the adhesion of the Glueless Patch. Isopropyl alcohol wipes in small outer packaging are effective and can be conveniently carried/packed together with the Glueless Patches. We strongly recommend Schwalbe Glueless Patches as they are thinner and therefore more flexible than comparable products from other manufacturers. With self-adhesive patches from other manufacturers, it can happen that small air channels form between patches and Aerothan Tube and thus air can escape from the tube again. (Addition: Defects in the transition of the sidewall to the tread are more difficult to seal. The reason for this is that a patch does not expand evenly in the radius to the tube and can become partially detached. This creates smaller air channels that can lead to faster air loss. Here it is advisable to use two patches overlapping. See below).

Can I repair larger defects on the tube with Schwalbe Glueless Patches?

For larger holes or cuts (max. 4 mm), it is recommended to use two patches overlapping the defective area. It is helpful to clean the defective area in advance with rubbing alcohol to improve the adhesion of the patch.

Can I use classic hose patches with vulcanizing liquid to repair a defect?

The use of classic hose patches is not recommended. The adhesive (vulcanizing liquid) is specifically designed for use on (butyl) rubber and will not hold permanently on Aerothan (TPU).

Can Aerothan Tubes be used with puncture sprays?

Puncture sprays will not achieve a seal on Aerothan Tubes because the thermoplastic polyurethane (TPU) has a very high surface tension. The use of puncture sprays in TPU tubes is not recommended due to the chemical composition. For optimum performance, Aerothan Tubes should be used without puncture sprays. Continuous use with puncture sprays is not recommended.

VALVE

What type and length of valve does the Aerothan Tube have?

The Aerothan Tube has a Sclaverand (SV) valve. Depending on the product, the Aerothan Tube is available with 40, 60, 80 and 100 mm stem lengths. Just like the tube, the valve stem is made of thermoplastic polyurethane and is also 100% recyclable.

Can the valve core be removed or valve extensions be used?

The valve core of the Aerothan Tube is screwed in and can be replaced if necessary. This means that the valve stem is also suitable for extensions.

Tip: Extensions should ideally be mounted with an anti-rotation device (Loctite). Schwalbe (Tubeless) valve extensions fit ideally to the Aerothan Tube (https://www.schwalbe.com/en/tire-accessories/valves/). Only extensions that are screwed into the Aerothan valve stem and have a screw-in limit should be used.

Valve cores for Aerothan Tubes have a special rubber sealing ring. For Schwalbe butyl tubes, valve cores with a Teflon seal are used. The mechanical and thermal properties of rubber harmonize much better in combination with the TPU material. This guarantees optimum sealing to the TPU valve stem.The valve stem does not fit through the valve hole of the rim. What can I do?

The valve stem diameter of the Aerothan Tube is matched to the standard diameter of a (SV) Sclaverand valve hole in a rim. Screwing in the valve core will cause the valve stem to expand minimally. This can lead to tight spots. In this case, the valve core should be unscrewed. Then guide the valve stem through the valve hole of the rim and screw the valve core back in. The valve stem must never be mechanically machined. This poses the risk of defects.

Can I use the Aerothan Tube with a rim that has an AV valve hole?

An AV valve hole has a diameter of approx. 8.5 mm. The SV valve of the Aerothan Tube has a diameter of approximately 6.1 mm. This difference can lead to noise while riding and puts above-average stress on the material. In this case, a reducing sleeve should be used, which is slid over the valve stem of the Aerothan Tube and holds the valve stem in the valve hole. Reducing sleeves or valve hole adapters are not offered by Schwalbe.

Can I use an AV adapter?

An AV adapter can be used. For a secure fit, this must be screwed approx. 3-4 thread turns onto the external thread of the valve core.

Why does the valve base rest on the rim bed during assembly?

The valve foot is tapered towards the hose. It serves as a support for the valve stem, thus counteracting strong mechanical effects, such as shear forces. The cone can rest on the rim well during assembly, but pulls minimally into the valve hole as air pressure increases. This ensures that the valve stem is held securely in the valve hole. The valve foot is made of the same material as the tube, so that there is uniform expansion of the tube and valve foot.

ASSEMBLY

How are Aerothan Tubes assembled?

The assembly of the Aerothan Tubes takes place as with any other bicycle tube. Thanks to the dimensional stability of the material, the tube does not slip easily and cannot be pinched, which makes assembly extremely easy. When inflating outside the jacket, however, the Aerothan Tube may only be filled with max. 0.3 bar.

Why should I only inflate the Aerothan Tube very carefully at the beginning?

The expansion of the Aerothan Tube is delayed compared to a conventional (butyl) rubber hose. The expansion therefore takes longer. When pumping the Aerothan Tube outside the tire, wait a short moment after each pumping stroke until the air is completely distributed and the tube has expanded. Excessive and too fast pumping can lead to blistering of the tube. The hose would then no longer be usable.

Why do the tubes discolor after mounting in the tires?

The transparent Aerothan material discolors upon contact with the tread compounds. This is due to diffusion of volatile substances released after the vulcanization process. This occurs particularly in new, unused tires. The discoloration has no effect on the performance or durability of the tubes.

Can I inflate Aerothan Tubes outside of the casing?

The Aerothan Tube can be inflated carefully outside the casing until it is wrinkle-free and has a round contour (corresponds to max. 0.3 bar).

Can I inflate the Aerothan Tube with CO2 cartridges?

Yes, but inflation with CO2 cartridge should only be done in fully installed condition. Outside the jacket, the Aerothan Tube should only be inflated carefully until it has a round contour and is wrinkle-free (corresponds to max. 0.3 bar), the CO2 cartridge is not suitable for this.

Can Aerothan Tubes be removed and reinstalled in another tire?

Yes, but reinstallation can only be done with the same or larger tire width.

Can I use Aerothan Tube with sealing milk?

Sealing milk will not achieve a seal with Aerothan Tubes because the thermoplastic polyurethane (TPU) has a very high surface tension. The use of latex-based sealing milk on TPU tubing is not recommended due to the chemical composition. For optimum performance, Aerothan Tubes should only be used in sleeves without sealing milk. Continuous use with sealing milk is not recommended.

Should I change my tires after using sealant milk to run Aerothan Tubes?

After using tires in tubeless mode, the tire must be cleaned of sealing milk residue as best as possible. Small, dried residues of the sealing milk must also be removed, as these can damage the Aerothan Tube through friction. In addition, certain ingredients in a sealing milk can cause damage to the TPU tube during long-term operation. In addition to the tire, the drop center of the rim or the rim tape should definitely be cleaned with brake cleaner or an alcohol solution.

I am on the road and have no way to remove the sealing milk completely. Can I still use the Aerothan Tube?

In the case that on the road a sealing milk can no longer seal the tire, the use of the Aerothan Tube as a first aid measure is of course possible, even without completely removing the sealing milk from the tire. The tube should then be cleaned as quickly and as thoroughly as possible with water and a cloth or rubbing alcohol. Under no circumstances should chemicals be used to clean the tube. The tire should be replaced depending on the size of the defect.

Can I use talcum powder when mounting the Aerothan Tube?

Talcum is not harmful to the AEROTHAN Tube. However, it is also not necessary to use it, since the AEROTHAN Tube is provided with a special lubricant due to its production. In addition, the friction between the TPU material of the tube and the rubber carcass of the tire is extremely low.

Is the Aerothan Tube suitable for rim brakes?

All Aerothan Tubes are approved for rim brakes. Aerothan Tubes are extremely heat-resistant and withstand high thermal loads (for example, in the course of emergency braking). In addition, the air does not escape abruptly in the event of an overload, which means that riding stability is maintained.

Can I use the Aerothan Tube with carbon rims?

All Aerothan Tubes are suitable for use with carbon rims. Again, the heat resistance of the Aerothan material is advantageous over latex and butyl.

Can I use Aerothan Tubes with tire pressure sensors?

Tire pressure sensors can be mounted if they are bolt-on systems. These are then screwed onto the visible external thread of the valve insert. Please check compatibility with the respective supplier.

Can I mount Aerothan Tubes with a rim tape?

A rim tape, properly used, is always an additional protection against defects. The Aerothan Tube is basically compatible with all common rim tapes. Optimal is the use with the Schwalbe Tubeless rim tape (https://www.schwalbe.com/en/TUBELESS-RIM-TAPE-887019). Always be aware of the correct width of the rim tape, matching the rim. If the rim tape in the rim bed is not clean from flank to flank, it can come to friction edge, which attack the tube. See also: https://www.schwalbe.com/en/technology-faq/rim-tape/

Can mini pumps with a screw-on pump head be used to mount the Aerothan Tube?

Mini pumps with a screw-on pump head (for example from Lezyne) can be used. For this purpose, the valve insert of the Aerothan Tube must be firmly seated in the valve stem. The pump head should be screwed onto the valve insert and unscrewed again with as little tension as possible. Optimally, the valve stem is held in place when screwing on and unscrewing and only the thread of the pump head is moved.

TIRE PRESSURE

What is the correct air pressure for Aerothan Tubes?

Thanks to their tremendous dimensional stability, Aerothan Tubes can be run at much lower air pressures than conventional bicycle tubes. For the correct air pressure, you can follow the recommendations for tubeless systems. It should be noted that the engraved minimum pressure on Schwalbe tires applies to the use of butyl tubes. When using Aerothan Tubes, the values can be undercut.

With the Schwalbe MTB Pressure Prof, the optimum air pressure in the tire can be calculated easily and quickly online:

What maximum tire pressure can Aerothan Tubes tolerate?

For the maximum pressure for Aerothan Tubes, the pressure range specified on the tire sidewall or rim should be adhered to. If the indicated pressure of the rim is lower than that of the tire, the maximum pressure of the rim must be observed. In case of uncertainty, contact the manufacturer.

How often do Aerothan Tubes need to be re-inflated?

Aerothan tubes are on par with butyl tubes in terms of air retention. Frequent re-pumping, as with latex tubes for example, is therefore not necessary. For optimal performance it is recommended to check the air pressure regularly.

Is there anything I need to consider when traveling by air?

The Aerothan Tube can be left in the tire without hesitation. It is recommended to slightly reduce the tire inflation pressure by one to two bars below the maximum allowable tire pressure. You can find tire inflation pressure information on the sidewalls of bicycle tires. Learn more at: https://www.schwalbe.com/en/technology-faq/special/

BUY AEROTHAN TUBE