WE RECYCLE

USED BICYCLE TIRES

AND TUBES

As a manufacturer, we take responsibility for our products - even beyond their life cycle. With the Schwalbe Recycling System, we take care of the return of inner tubes and tires in order to then recycle them and avoid unnecessary waste. The aim is to use the recovered material in the production of new goods and to further increase the proportion of recycling. With this we want to take an important step towards the circular economy.

„WE TREAT RECYCLING LIKE A PRODUCT AND HAS THE SAME PRIORITY AS ANY TECHNICAL INNOVATION.“

HOLGER JAHN - COO

SCHWALBE TIRE RECYCLING

COLLECTION

TRANSPORT

SHREDDING

- Steel

- Tissue

PYRUM THERMOLYSIS

- pyrolysis oil

- process gas

RETURN

As the first bicycle tire manufacturer in the world

we take care of the return and recycling of used bicycle tires of all brands. The completely closed circulatory system contributes proactively to the conservation of energy and resources and saves 80% CO2. This holistic recycling process was awarded the Eurobike Innovators Prize.

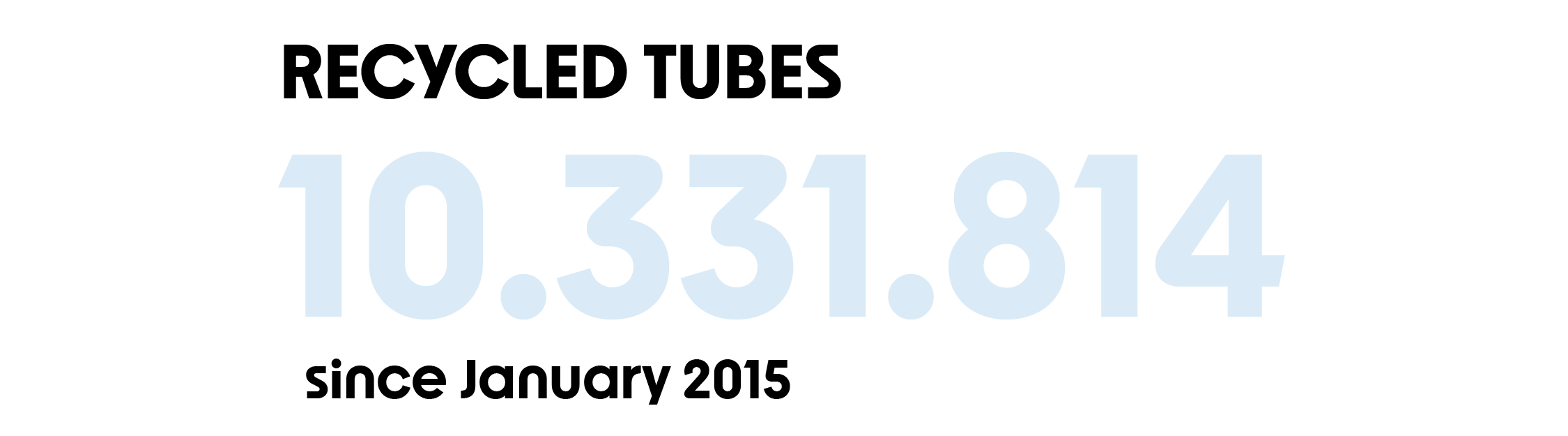

SCHWALBE TUBERECYCLING

100%

RECYCLABLE

Every Schwalbe tube is 100% recyclable. The recycled one Butyl rubber can be used in the production of new hoses without loss of quality are used.

STARTING- MATERIAL

Used, unsorted hoses are the starting material for recycling. In Germany, the Netherlands, Great Britain and now also in Switzerland, we support the return process of old bicycle inner tubes with a collection procedure in which both bicycle dealers and end users can participate easily and free of charge.

PROCESSING

To recover the butyl rubber, a proprietary devulcanization process was developed at the Schwalbe plant in Indonesia. This method has been used very successfully for years.

80% LESS

POWER CONSUMPTION

The energy balance of this recycling process is extremely positive, including all transport routes. 80% energy saving compared to producing the same amount of new butyl.

THE NEW TUBE

Every new Schwalbe standard hose already consists of around 20% recycled raw materials. We are constantly working on further increasing the proportion of reused material without adversely affecting the quality of the new hose.

Schwalbe tube recycling was awarded the Eurobike Green Award 2015, the Green Concept Award 2020 and the German Sustainability Award 2021.